Innovating ahead of the pack

Solutions that pack the power of emergent technologies

Automation

Replace manual handling with fully automated solutions that accelerate your production flow, ensure consistency, and contain your costs.

Scalability

Gain agility and versatility with right-sized packaging solutions that can easily switch between product lines and formats.

Digitalization

From real-time overall efficiency metrics to advanced marking software, our digital solutions use data to drive your business forward.

Remote access

Remote access makes it easier to analyze the performance of your machines, so you can proactively identify and address issues for increased uptime.

Automate your processes and accelerate your flow

Manufacturers of all sizes face the cost challenge of labor-intensive product handling processes. We can design, develop, and implement a robot packaging machinery (RPM) solution that seamlessly automates these tasks within your current and future production processes.

As an integrated solution provider, we also develop robotic human machine interface (HMI) software that keeps you in the driver’s seat. Now you can easily reconfigure your production line for format or recipe changes and the machinery will adjust automatically.

Benefit from agility and scalability

We offer flexible packaging machine solutions to suit any production floor size or layout, with capacity that can expand over time to keep pace with your evolving business.

Our technology solutions are customized to your production needs – from large high-capacity runs with many processing options, to smaller runs where frequent format changes are necessary.

Gain speed and security with digitized production

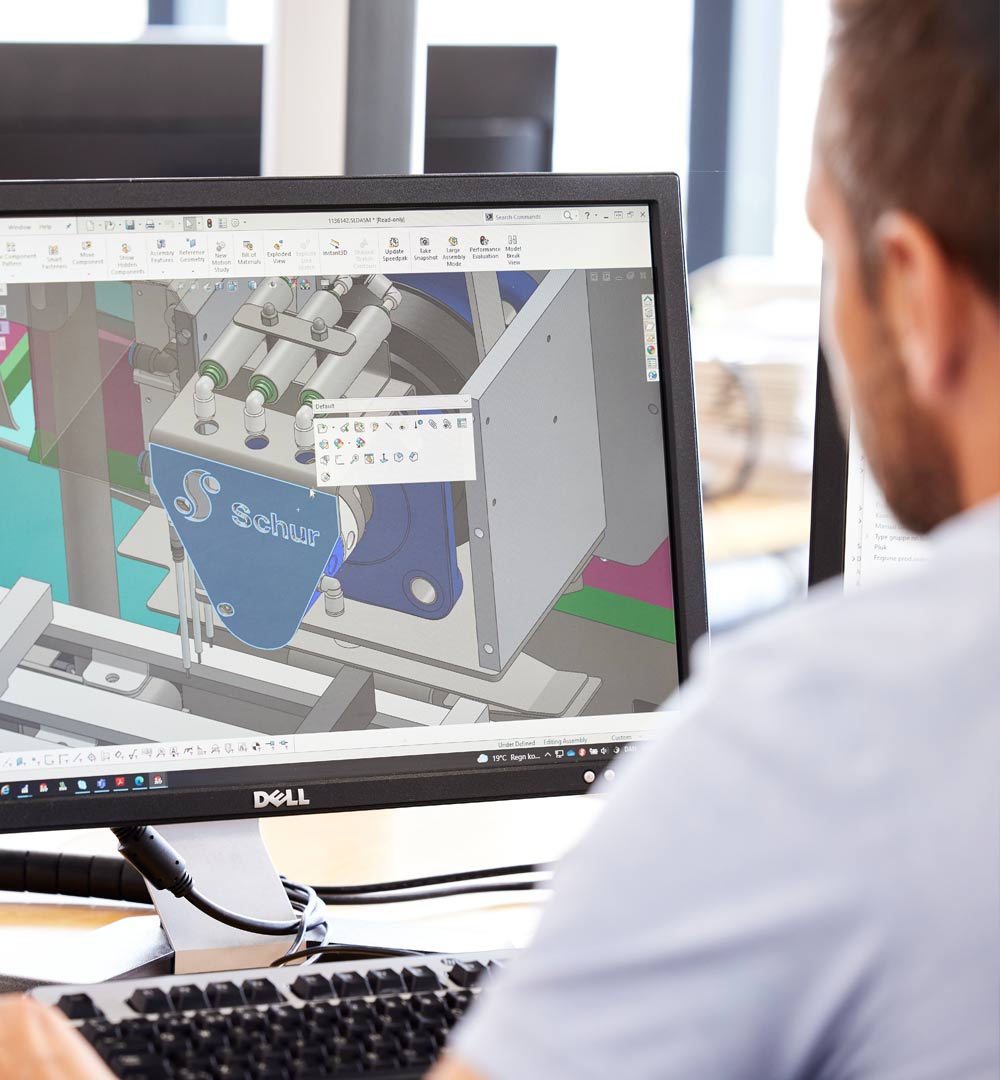

We are continually merging hardware and software solutions in order to accelerate your production flow and assure product quality. Connecting your machines to your ERP system gives you a real-time overview of where every component is in your process, without relying on manual documentation.

Digitizing manual tasks, such as data marking for production times and batch coding, brings significant additional cost and assurance benefits. By centralizing data control from one point, you can ensure the right data is in the right place at the right time. This minimizes the risk of human error and the unnecessary waste and delay that can occur as a result.

Stay up and running with advanced IOT monitoring

The internet of things (IOT) is one of our growing areas of expertise. Intelligent sensors, server motors and drivers can deliver process and quality data directly into your HMI, and we are already building these capabilities into our packaging technology solutions.

As well as giving you proactive control over all your production line components, it also allows our technicians to remotely and securely analyze your machine data. Whether you are troubleshooting a technical issue, or need help with a complex format change, we have the access and insights to help you maximize capacity and minimize downtime, wherever you are, and wherever you need us.

Any questions?

Ask one of our experienced consultants in your local area.